In 1996, a young man named David Spathaky set a world record for keeping 108 plates spinning simultaneously on sticks scarcely larger than a pool cue.

That feat of poise, precision, and determination pales in comparison to the balancing act often faced by today’s commercial building architect.

Consider the building envelope, for example: Balancing the requirements of the owner’s vision, code, sustainability, budget, and design intent takes a special brand of resourcefulness and insight.

When selecting an envelope assembly, architects have to ask themselves: “Is the cladding ASHRAE 90.1 compliant?” and “What about the fire rating? Red list issues? Code? Transitions and details? Wind load? LEED objectives? Color fastness? Warrantability? Moisture and air barriers? Insulation? Installation ease?”

Maneuver through that thicket and you still face possible liability concerns should any question go sideways. That’s a lot of pressure and risk.

Few outside observers know those challenges better than Brandon Kinsey and Brian Finnegan, both regional architectural sales managers for CENTRIA, a large manufacturer of insulated metal panels (IMPs), a cladding system known for its crisp, engineered facades. Architects frequently consult with the veteran advisors on cladding matters. “We’re involved very, very early—when the design intent may be little more than ideas sketched on a napkin,” Kinsey says.

The challenge is that there are many cladding options today, including metal composite material, aluminum composite material, fiber cement, EIFS, terra cotta, zinc, brick, glass, and IMPs, to name a few. All have their merits. The differentiators, say Kinsey and Finnegan, often come down to specification confidence, simplicity, and budget. Each consideration plays well to IMP’s strengths:

- Confidence. Specifying IMPs can safeguard the owner’s investment for many years. CENTRIA, for example, “… takes full cladding responsibility for everything from the inner vapor and air barrier to the exterior cladding. We’re on the hook for 20 years,” Finnegan says. CENTRIA IMPs also comply with all code requirements, including the NFPA 285 fire test standard.

- Simplicity. IMPs are structural steel panels (not aluminum) with available panel sizes of up to 10 feet. That dramatically reduces the need for falseworks, saving considerable labor expenses, materials, and packaging waste. Red list-free foam is also integrated into some panels, offering insulation values of up to R-22. You can build right over stud material without extra barriers. Less wall assembly material means an inherently greener structure, which can be recognized with LEED points.

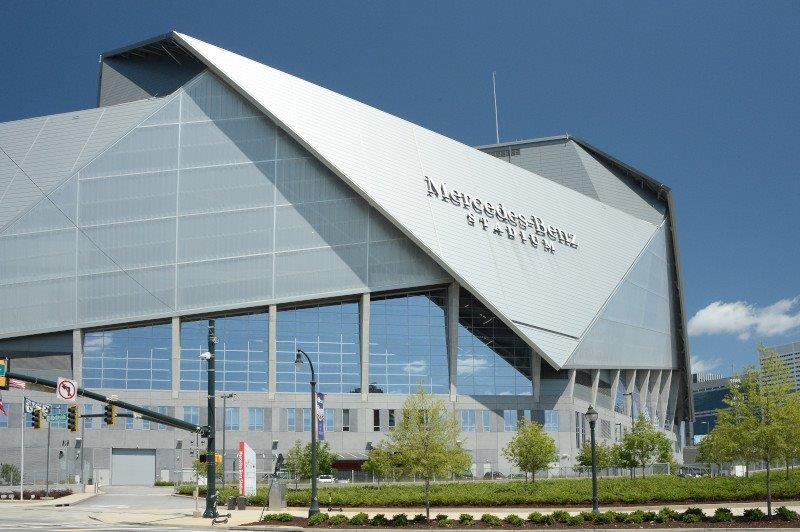

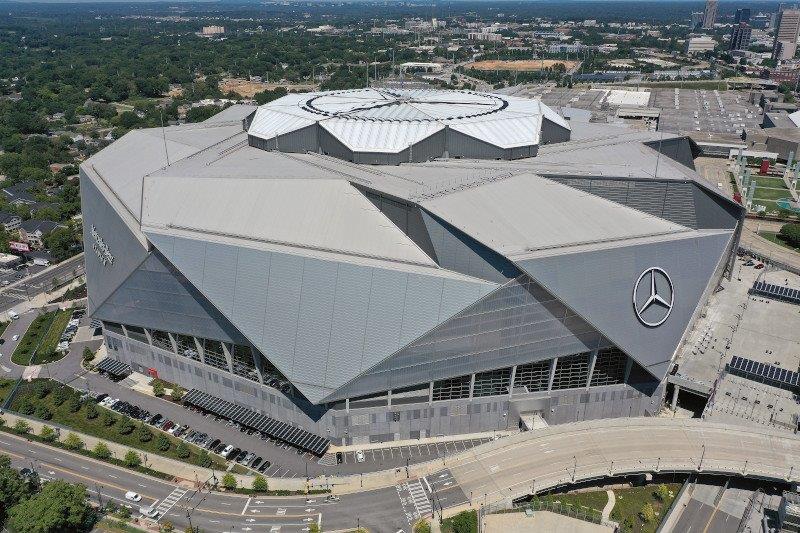

- Budget. Architects seeking terra cotta, zinc, natural stone, masonry, or other high-end design effects will be pleased by what is possible with IMPs. The system’s broad use in large-scale projects such as stadiums, convention centers, schools, hospitals, government service, and aviation hangars illustrates the material’s exceptional value across many applications.

No cladding solution is perfect. Compare EPDs. Samples. Project histories. As you investigate alternatives, keep IMPs on the shortlist. IMPs merit special consideration on any project where confidence, simplicity, and budget are key to project success.

Learn more about designing and building with insulated metal panels.