Regarded as the building industry’s gold standard, the U.S. Green Buildings Council LEED certification program offers a long list of economic, health and wellness benefits. From its introduction in 1998 to late 2019, the USGBC had already reached the milestone of registering and certifying 100,000 commercial projects.

The four-tiered system offers a basic certification, silver, gold and platinum, and is based on a 110 point system where buildings can earn credits in eight different categories.

Boosting an organization’s commitment to sustainability and public image, LEED-certified buildings have been proven to deliver significant energy efficiencies and cost savings.

In fact, after analyzing the monthly energy consumption data of more than 175,000 commercial buildings in Los Angeles over a period of seven years, in “The effectiveness of U.S. energy efficiency building labels,” UCLA and Georgia Tech researchers reported 30 percent more energy savings in LEED-certified buildings.

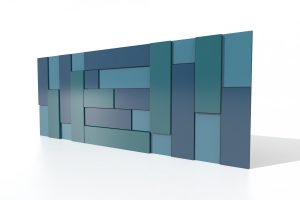

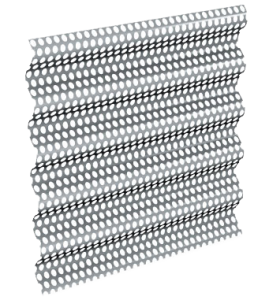

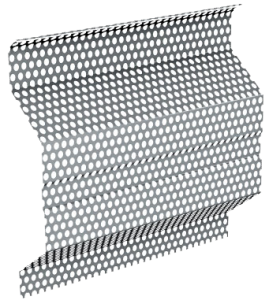

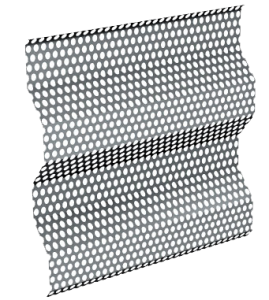

CENTRIA’s Formawall® insulated metal panels and EcoScreen® perforated panels contributed toward a LEED Platinum certification for Mission College’s Student Engagement Center in Santa Clara, Calif.

In another study, the U.S. Department of Energy’s Pacific Northwest National Laboratory reports close to 20 percent lower maintenance costs for LEED buildings as compared to a typical commercial building.

Further, a Porter Novelli-conducted survey of more than 1,000 workers found that a high percentage of employees prefer LEED-certified facilities with 79% prioritizing a job in a LEED building and more than 80% reporting enhanced productivity in these settings.

“Studies have found that LEED-certified buildings can help companies attract talented employees,” states Don Catalano, president and CEO of the Melville, N.Y.-based commercial real estate consultant REoptimizer. “Plus, worker satisfaction in LEED-certified offices tends to be high, decreasing employee turnover.”

In one of these studies, “The Impact of Green Buildings on Cognitive Function,” Harvard and SUNY researchers found that occupants of high-performing green buildings showed higher cognitive function scores, fewer sick-building symptoms and higher sleep quality scores than workers in high-performing buildings without green certification.

"Green certification, thermal conditions and lighting influenced worker perception of their space as well as their cognitive function,” states Joe Allen, assistant professor at Harvard University’s School of Public Health and co-author of the report. “Good companies know the value of providing a healthy workspace. Healthy buildings are a recruiting tool, after all.”

Metal Panels and LEED

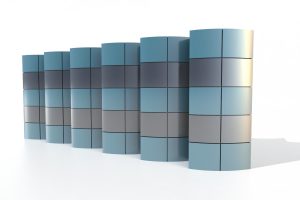

While a number of green building materials, systems and strategies can help building owners qualify for LEED certification, high quality metal roofing and panels are particularly effective toward this end.

In a Metal Construction Association-sponsored continuing education unit on sustainability, Gloria D. Lee, principal, Swift Lee Office Architects, Pasadena, Calif., states, “Metal walls and roof systems contribute to a high-performing building envelope in so many ways.”

The panels are long-lasting, low maintenance, moisture and mold resistant, and thermally efficient, and the roofs offer a high solar reflectance index (SRI) to keep roofs and interiors cooler. Metal roofs can also be integrated with photovoltaic and rainwater harvesting systems for enhanced energy and water efficiencies.

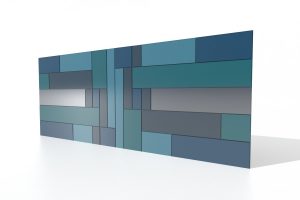

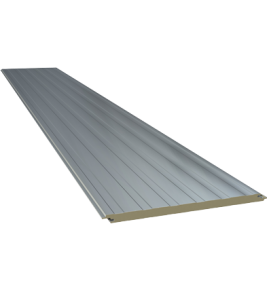

CENTRIA’s Formawall® system played an important role in helping Pittsburgh’s Tower 260 achieve LEED Silver certification.

CENTRIA’s Formawall® system played an important role in helping Pittsburgh’s Tower 260 achieve LEED Silver certification.

Breaking it Down

For LEED v4’s eight categories, metal walls and panels can directly contribute to credits in four main areas and indirectly in an additional two areas.

Sustainable Sites – By meeting designated initial and three-year aged Solar Reflectance Index values for steep slope and low slope roofs in the Heat Island Effect category, buildings can earn up to 2 points with cool metal roofs and coatings. Because prefabricated metal systems require a minimal staging area, they support the pursuit of an additional point through Site Development. In addition, metal roofs are a great platform for Rainwater Management which can help projects earn up to 3 points.

In turn, rainwater management can contribute to Outdoor Water Use and Indoor Water Use credits in the Water Efficiency category.

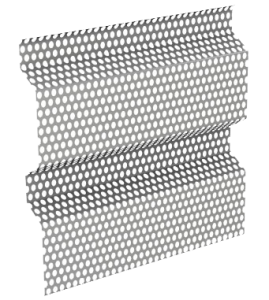

Energy and Atmosphere – For Optimize Energy Performance, metal systems can help buildings cash in on a windfall of LEED points. With its high insulating value and thermal performance, insulated metal panels (IMP), for instance, can contribute up to 18 points. As validated through energy models, thermal efficient building enclosures support downsized HVAC systems and reduced electrical loads. Though indirect, metal facades and roofs incorporate windows and skylights, which, along with perforated panels, support up to 3 points in Daylight credits. In addition, metal roofs support PV panels and solar thermal systems to garner up to 3 points for Renewable Energy Production.

Materials and Resources – IMPs can also make a significant contribution in a number of categories here. Starting with Building Life Cycle Impact Reduction, up to 5 credits are available for optimized environmental performance of products, materials and adaptive reuse. Another 3 points are available for performing a Whole-Building Life-Cycle Assessment with the assistance of Environmental Product Declarations (EPDs), which many building product companies, particularly metal panel manufacturers have developed. EPDs can add another point for Building Product Disclosure and Optimization, a category which grants a second point for Sourcing of Raw Materials.

Another subcategory is Material Ingredients where projects can earn one point toward Building Product Disclosure and a second credit via Optimization. With its high recycled content, metal panels are a great advantage here.

For Construction and Demolition Waste Management, prefabricated metal systems significantly reduce waste, contributing up to 2 points.

Indoor Environmental Quality – By specifying products and systems, such as metal walls and roofs with Low-Emitting Materials, another 3 points can be collected here.

Making the Grade

As building owners and architects evaluate many materials, products and systems in their quest to design a LEED-certified building, high quality metal roof and wall panels are a great way to get there.