The metal building industry continues to grow and evolve, which may be spurred on by the hopefulness of a post-pandemic world later this year. This is a good time, then, to get updated on some of the trends and developments that have been emerging in the past few years and are likely to continue strong into the foreseeable future. Some of the most notable innovations that are fast becoming trends in exterior metal wall panels and facades are as follows:

Finishes: The latest exterior metal panel coatings are a pre-finished decorative system that accurately simulates more expensive natural finishes, including wood and specialty metals. Using high performance, field-proven print coating technology, an innovative metal print coat finish system can be used on both steel and aluminum substrates, offering significant cost savings along with lower maintenance than the natural materials they emulate. The coating is available in twelve print coat patterns and colors, is low maintenance, offers exceptional dirt and stain resistance, and provides excellent UV resistance. Further, the outstanding adhesion and color consistency of these coatings means that the panels will continue to look uniform over the life of the buildings they are used on. CENTRIA offers finishes that do all of this under the “Impressions” line.

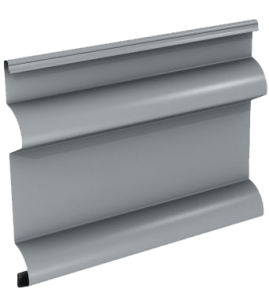

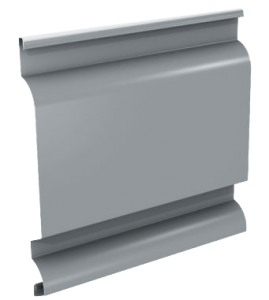

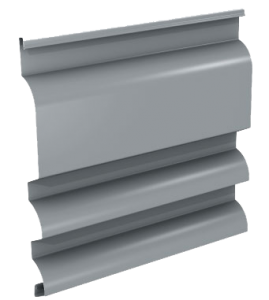

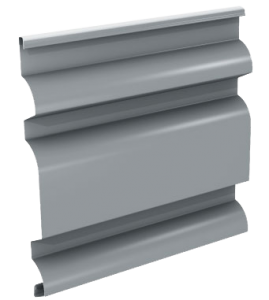

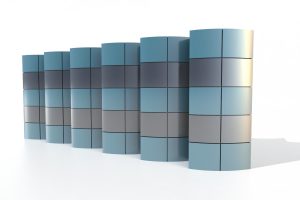

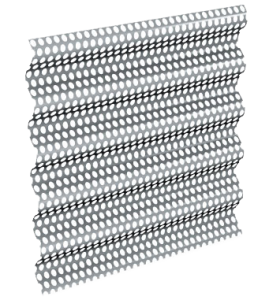

Bold Three-Dimensional Facades: Metal panels used in single-skin rainscreen façades are now readily available with curves and bold, sloped-rib profiles. While corrugated metal panels have been available and in use for some time, these new panels use the play of light and shadow to create a complex wall relief that has not been available before in corrugated metal wall panels. In addition to innovative aesthetics, the same performance associated with conventional metal rainscreen products can be achieved. The panels may be installed in a variety of horizontal or vertical rainscreen applications to form a complete wall system. The “Cascade” line is offered by CENTRIA as part of this visual trend.

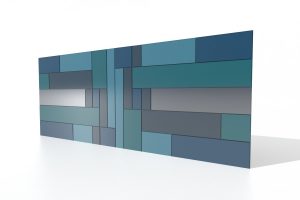

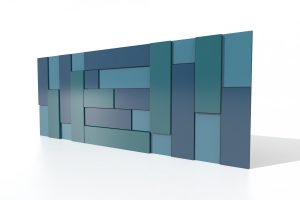

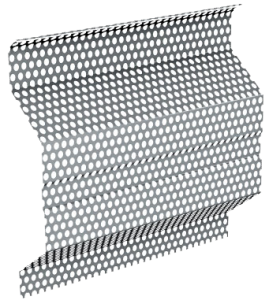

Modular Aesthetics: A modular metal panel system can change conventional thought on what a rainscreen wall system should look like. A coordinated system of smaller, modular panels in a variety of colors and finishes can be used by artistic façade designers to inspire spectacular visual results. Since there are plenty of finish choices, the combinations of patterns and appearances is only limited by the designer’s imagination. The modular design of such a system means that either vertical or horizontal installations can be incorporated. Modular metal panels are available in standard coil-coated aluminum substrate, post-anodized aluminum, zinc, and other natural metals. Further, they are available in a variety of panel design options including flat, tapered, or perforated. The “Intercept” product line is the CENTRIA system that can be used to take advantage of this trend.

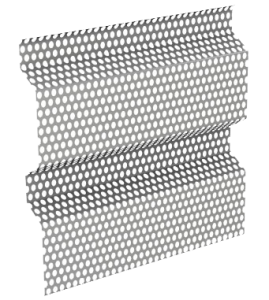

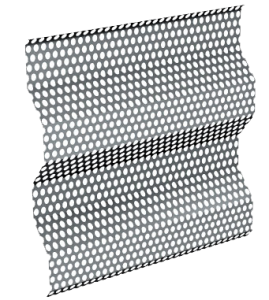

Perforated Panels: There are design and performance reasons where certain facades can benefit from a light, airy, aesthetic or allow air to flow through on purpose. In these cases, a perforated metal panel can be the best choice. Typically, such panels are created using a unique fabrication process applied to 20-gauge stainless steel or 0.040" painted aluminum. This means that the building can blend with their surroundings with a material that will hold up very well over time. The amount of perforation can vary and be specified between 10% - 40% of the panel area to provide an airy aesthetic that controls light and air movement making it an ideal choice for concealing equipment. The panels can be installed either vertically or horizontally to suit particular project needs. CENTRIA offers perforated panels in a variety of product lines, but a full system is found in “EcoScreen Perforated Screenwalls”.

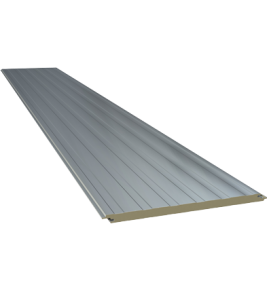

Insulated Metal Panels: The combination of rigid foam insulation and an interior and exterior metal skin produces insulated metal panels (IMPs). Used in commercial and industrial buildings where energy performance and expedited construction processes are important, IMPs provide a one-step solution to provide interior and exterior finish, insulation, plus an effective air and vapor barrier. The lightweight panels provide tremendous design flexibility, ease of installation with long lengths, various finish options. and superior weather resistance. They can be installed vertically or horizontally to suit the aesthetics of large-scale commercial and industrial buildings such as warehouses, industrial facilities, schools, and shopping centers. From a performance standpoint, the insulation creates a thermal break between the face and liner to save energy. A factory-applied panel joint sealant, together with field-applied sealant, create an air and vapor barrier that provides outstanding results. They are also available with factory-formed sheet metal flashing or extruded aluminum trim. The “Versawall” (vertical or horizontal) product line is offered by CENTRIA in this category of trending metal walls.

To find out more about any of these trends in building facades that use metal panels, visit the CENTRIA website or contact your local CENTRIA Representative.