Energy plant unifies the $88 million WakeMed North Healthcare Campus.

The central energy plant serves an important role as the electric and HVAC heart of many academic or healthcare campuses. All too often, though, the overlooked facilities are geared toward a utilitarian, design-challenged aesthetic. After all, it's just the central energy plant, right?

Not to Ryan Wilborne, AIA, LEED AP, at BBH Design, a Raleigh, N.C.-based full-service design shop specializing in healthcare and higher education projects. Wilborne takes polite exception to the central energy plant’s ugly duckling status: “Infrastructure buildings can be beautiful.”

As evidence, he points to the firm’s recently completed assignment for the $88 million WakeMed North Family Health & Women’s Hospital in Raleigh. The new 248,800 square foot facility is powered by a new 12,000 square foot, $9 million central energy plant, located on the healthcare campus. The entire project is targeted for Gold LEED certification under the healthcare pilot program category.

The new energy plant bristles with the expected high-tech generators, boilers, chillers, and control technology, all scaled to the hospital’s sizable needs. Up top, the plant includes three large and unsightly cooling towers.

Blending Function and Form

“We applied the same design attributes to the energy plant as we did the main campus,” Wilborne, the project architect, says. “We wanted to keep everything very clean and consistent, with the energy plant minimally included in the overall design aesthetic.”

To conceal the trio of cooling towers, Wilborne says “we thought it would be nice to have a delicate screen around the towers. The screen kind of pulls off the front of the building with an interesting offset effect. The corrugation of the plant panels is the same found on the main hospital panels, though the plants are perforated.”

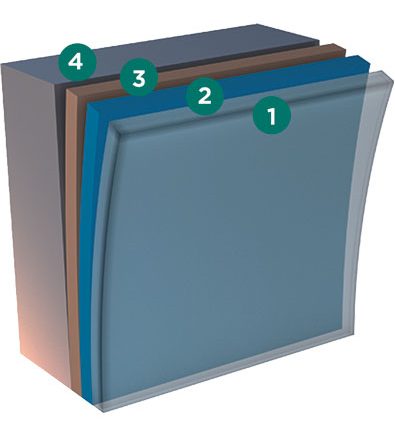

To conceal the towers, the BBH team specified 2,567 square feet of CENTRIA’s Concept Series CS-660 with MicroSeam Corners in slate gray and 5,043 square feet of EcoScreen perforated screenwall.

Design-Friendly Perforations

The perforations allow the free flow of air and aid the design process by allowing close-in panel placement to the towers. The rooftop panel system is supported by a galvanized tube-steel.

With perforations, care must be used to anticipate back-lighting and perforation size/arrangement. The wrong combination of backlight and perforation could make the panels virtually invisible at night. “The CENTRIA panels do exactly what we want them to do—they hide the stuff we don’t want to see, but still function as light and airy design elements day or night,” Wilborne’s colleague and Project Manager Rob Anastes, AIA, observes.

Panel Specification

The decision to specify CENTRIA was an easy one, Wilborne says. “We use CENTRIA as the basis of design and they came in as the most cost-effective supplier. We’ve had a lot of good luck with CENTRIA products. We use them a lot and they’re our go-to source for metal paneling.

“CENTRIA is great to work with. They’ll help us with custom things, like custom detailing. Buildings are never perfect, so you always have spots that require custom touches. CENTRIA offers great solutions.”

Inner Swan Unleashed

As for the new WakeMed North central energy plant, the owner is very happy, Wilborne reports. So is central energy plant design becoming a new BBH design specialty?

Wilborne says it’s not something they set out to do, but welcome it as a necessary part of the project, like a parking deck. “We have designed half a dozen really nice energy plants. If care is given to these buildings, it can really have a nice effect.”

An ugly duckling? Let a little design magic unleash the energy plant’s inner swan!