While there is a plethora of metal panel systems in the market, very few, if any, offer a high level of expertise and support throughout all stages of a building project.

With its dedicated stable of designers and engineers waiting in the wings, CENTRIA is the exception.

Even before a project goes to bid, CENTRIA’s experts can address product applications, metal panel options, custom details and ensuring the desired design is installable. The team is on hand in a design-assist capacity through final installation and even afterwards, providing engineering design support to improve an as-built condition.

Whereas many companies will present a metal panel option, explain in general terms where it can be applied and then disappear, CENTRIA sees its project through, giving a level of support that is unique to the industry.

Another differentiator is the company’s diverse product line and ability and willingness to highly customize systems to meet an architect’s unique design needs.

For example, the selected insulated metal panel system might butt up against a rainscreen, which would require some custom trims and extrusions to make it work. Many manufacturers would not invest in such a project, or might not have the expertise to execute such a design. On the contrary, CENTRIA embraces these challenges, rolls up its sleeves and comes up with a solution.

“We like to push the ‘never say never’ attitude and don’t get stuck only coloring in between the lines,” relates Ralph Bertram, product applications manager, CENTRIA. “We really push our designs further with additional customization. Designed to last the life-time of a structure, we hang our hat on that and take a lot of pride.”

For example, the architect might want to specify a particular panel, but it may not be the best choice for the application or budget. Rather than turning down the project, CENTRIA’s team of internal detailers and structural engineers will put their heads together to come up with alternatives to meet the project’s performance and aesthetic needs.

The solution might be as simple as suggesting that the metal panel be attached with a metal stud as opposed to a wood frame, but whatever the case may be, CENTRIA’S experts are on hand to make the project work.

Repeat Customers

The long-term result of this level of customer service is a stable of architecture firms turning to CENTRIA for its metal paneling needs. Take Ewing Cole, for example. Ranked #18 on Building Design+Construction’s top architecture/engineering firms list, Ewing Cole recently collaborated with CENTRIA to upgrade Clover Park, the New York Mets Port St. Lucie, Fla. training facility and minor league ballpark.

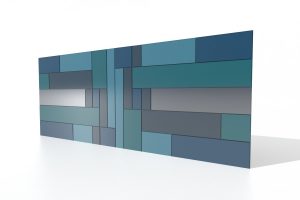

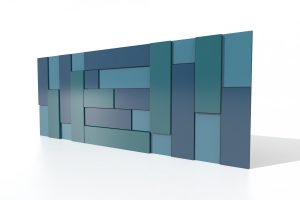

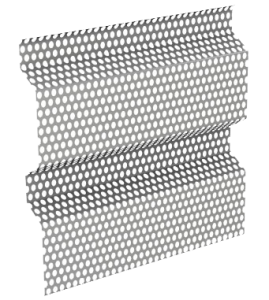

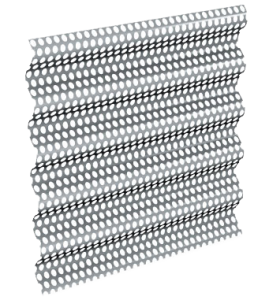

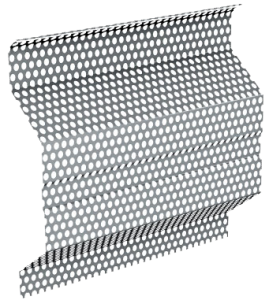

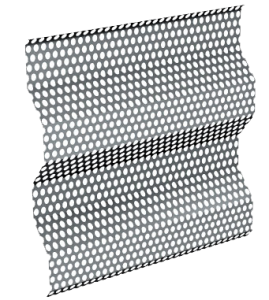

Working hand-in-hand with the architect, CENTRIA customized 17,000 square feet of Intercept Entyre modular metal panels, 8,000 square feet of CS- 200 concealed fastener panels and 1,000 square feet of perforated EcoScreen BR5-36 screenwalls.

Meeting hurricane zone requirements and providing a high level of UV ray resistance, the Intercept Entyre system was ideal for this Sunshine State project. CENTRIA’S engineers worked closely with Ewing Cole to develop customized Intercept Entyre ¾” and CS-200 concealed fastener panels in a custom Mets blue, Gentian Blue, yellow and orange colors. The interactive fins line the ballpark’s exterior, showcasing famous Mets players.

Another Ewing Cole project called for CENTRIA’s Concept Series CS-660 panels with MicroSeam Corners and Ecoscreen Perforated Screenwall for the WakeMed Central Energy Plant supporting WakeMed North Hospital in Raleigh, N.C. The system’s concealed fastener panels and common-lock joinery supports Ewing Code’s custom ventilated metal design. Stand-off clips ensure proper ventilation and a drainage plane, and allows for thermal and seismic movements.

The perforated screenwall supports airflow and close-in panel placement and the corrugated style matches the panels on the main hospital.

Standing Out in the Crowd

From sports arenas to hospitals to museums to bio-tech companies to schools, CENTRIA offers industry-leading metal panels for aesthetics, sustainability and design flexibility.

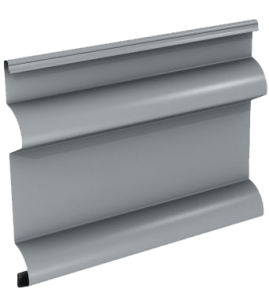

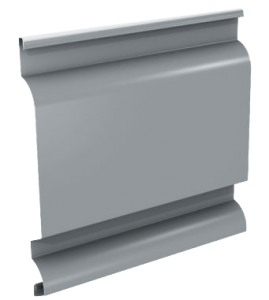

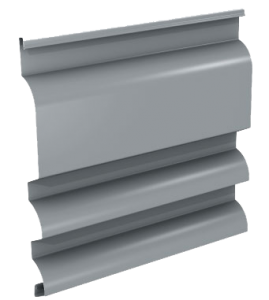

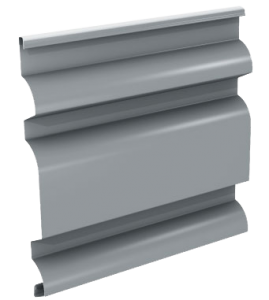

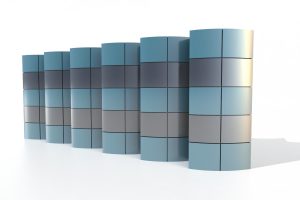

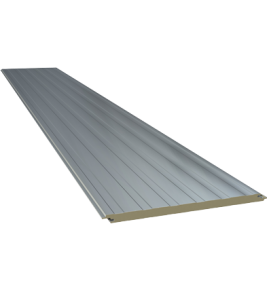

In applying a big spool of steel coil, CENTRIA’s unique manufacturing process involves leveling the steel to make it extremely flat and smooth, which is a very sought after industry feature. Together with an embossed finish, this covers up any imperfections and delivers a very high-end architectural panel. In addition, the insulating foam bakes into the metal panel, as opposed to lamination, thereby eliminating air pockets.

The foam is made from halogen free, environmentally friendly polyisocyanurate and the panels are treated with coatings containing PVDF resin for a more durable finish.

The panels come in an extensive palette of sizes, profiles, textures and colors, and as noted, can be highly customized to meet every project’s unique needs.